JBM-11

Bronze Backed with Bronze Powder PTFE/Fibre

Features & Benefits

Optimized for dry running environments, featuring a low coefficient of friction, minimal wear, and superior sliding properties. The resulting transfer film effectively protects mating metal surfaces. Well-suited for both rotary and oscillating motion, this material exhibits exceptional chemical resistance, low water absorption, and resistance to swelling. It also maintains excellent performance in lubricated applications. Notably, the bronze backing offers enhanced corrosion resistance compared to the JBM-50 series.

Structure

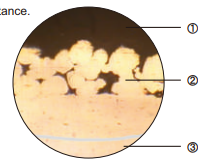

| Layer | Material | Thickness | Function |

|---|---|---|---|

| 1 | PTFE/fibre mixture | 0.01~0.03mm | Provides an excellent initial transfer film, effectively coating the mating surfaces of the bearing assembly to form an oxide-type solid lubricant film. |

| 2 | Sintered bronze powder | 0.20-0.35mm | Ensures maximum thermal conductivity away from the bearing surface and serves as a reservoir for the PTFE/Fibre mixture. |

| 3 | Bronze backing | Base | Delivers exceptionally high load-carrying capacity, superior heat dissipation, and excellent corrosion resistance. |

Technical Data

max load

- static 250 N/mm²

- very low speed 140 N/mm²

- rotating oscillating 60 N/mm²

max pv dry running

- short term operation 3.6 N/mm²*m/s

- continuous operation 1.8 N/mm²*m/s

temperature limit

friction coefficient

max speed

- dry running 2 m/s

- hydrodynamic operation >2 m/s

thermal conductivity

coefficient of thermal expansion

Typical Applications

Iron & Steel

Bushings for roller grooves in continuous casting machines.

Learn More

Hydraulics & Valves

Cement grouting pumps, screw conveyors, and other heavy-duty equipment.

Learn More

Oil & Gas

Ideal for applications where oil lubrication is inefficient or impossible, and where machinery must withstand continuous, long-term operation.

Learn MoreLooking for other bearing solutions?

Browse All ProductsNeed Help with JBM-11?

Our engineering team can help you determine if this bearing is right for your application. Get personalized recommendations, technical datasheets, and competitive pricing.

Contact Us