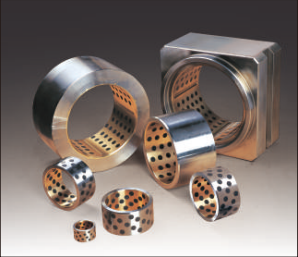

Metallic Self-Lubricating Bearings

Cast bronze bearings with embedded graphite plugs for extreme temperatures, heavy loads, and maintenance-free operation in the harshest industrial environments.

How Solid Lubricant Bearings Work

Unlike polymer composite bearings that rely on a thin coating, metallic self-lubricating bearings use solid lubricants embedded directly into the metal matrix. The cast bronze base provides exceptional mechanical strength, while graphite plugs distributed across the bearing surface provide continuous self-lubrication.

Film Transfer Principle: During operation, friction generates heat that causes the solid lubricant (graphite) to release and form a protective transfer film on the mating shaft surface. This lubricating film is continuously replenished, enabling true maintenance-free operation without external grease or oil.

Why Choose Metallic over Polymer?

- Higher Load Capacity: Cast bronze withstands static loads up to 100+ N/mm²

- Extreme Temperature Range: Operates from -40°C to +400°C (vs. +110°C for POM, +280°C for PTFE)

- Superior Impact Resistance: Solid metal construction absorbs shock and impact loads

- Contamination Immunity: Performs reliably in dirty, dusty, underwater environments

- Zero Maintenance: No re-lubrication required throughout service life

Technical Specifications

| Base Material | Cast Bronze Alloy |

| Lubricant | Graphite + Additives |

| Max Static Load | > 100 N/mm² |

| Temperature Range | -40°C to +400°C |

| Max Speed (Dry) | 0.5 m/s |

| Max Speed (Lubricated) | 1.0 m/s |

| PV Limit (Dry) | 1.65 N/mm²·m/s |

| Lubrication | Maintenance-Free |

Cross Reference

Equivalent to Oiles 500# Series, JDB / JPF / MPBZ Type, Graphite Plugged Bronze Bushings, Oil-Free Bearings.

Material Grades & Chemical Composition

JBM metallic self-lubricating bearings are available in multiple bronze alloy grades, each optimized for specific operating conditions. Choose the right base material for your application.

High-Strength Brass

CuZn25Al5Mn4Fe3The most widely used alloy for heavy-duty applications. Excellent combination of strength, wear resistance, and corrosion resistance.

Chemical Composition

- Cu Balance

- Zn 22-28%

- Al 4-6%

- Mn 3-5%

- Fe 2-4%

Best For: Steel mills, mining, construction machinery

Aluminum Bronze

CuAl10Ni5Fe4Superior corrosion resistance for marine and offshore applications. Excellent performance in seawater and corrosive environments.

Chemical Composition

- Cu Balance

- Al 9-11%

- Ni 4-6%

- Fe 3-5%

- Mn ≤ 2%

Best For: Marine, offshore platforms, ship rudders

Tin Bronze

CuSn12Traditional bearing bronze with excellent wear characteristics. Good for moderate speeds and loads where lower cost is preferred.

Chemical Composition

- Cu Balance

- Sn 11-13%

- P 0.3-0.5%

- Pb ≤ 0.5%

- Zn ≤ 0.5%

Best For: General industrial, moderate loads

Embedded Lubricant Types

SL1 - Graphite Based

Temperature Limit: 400°C

Standard graphite lubricant for general machinery and atmospheric applications. Excellent high-temperature performance.

Applications: Steel mills, furnaces, general industrial

SL4 - PTFE + MoS₂ Based

Temperature Limit: 300°C

Advanced composite lubricant optimized for water and seawater environments. Lower friction coefficient.

Applications: Marine, underwater, dam gates, hydraulic turbines

Why JBM Metallic Self-Lubricating Bearings

Extreme Temperature

Operates continuously up to 400°C with graphite lubricant. Ideal for steel mills, furnaces, and hot metal processing.

Heavy Load Capacity

Cast bronze base handles static loads exceeding 100 N/mm². Perfect for mining equipment, presses, and construction machinery.

Zero Maintenance

Self-replenishing graphite film eliminates re-lubrication requirements. Reduces maintenance costs and equipment downtime.

Water & Marine Ready

SL4 lubricant variant enables reliable operation in water, seawater, and offshore environments where oil lubrication fails.

Impact Resistant

Solid bronze construction absorbs shock loads and vibration that would damage polymer bearings.

Contamination Immune

Performs reliably in dusty, dirty environments. Solid lubricant plugs cannot be washed away or contaminated.

Oscillating Motion

Optimized for slow, intermittent, and oscillating movements typical in heavy machinery pivots and linkages.

Custom Shapes

Cast bronze can be machined into bushings, wear plates, thrust washers, and custom shapes for any application.

We typically respond to inquiries within 12 hours. Get expert recommendations for your application.

Get a QuoteWhere Metallic Self-Lubricating Bearings Excel

When polymer bearings can't handle the heat, load, or contamination, metallic self-lubricating bearings deliver. Engineered for the world's most demanding industrial environments.

Steel & Metallurgy

- Continuous casting machines

- Rolling mill roll chocks

- Ladle car pivots

- Furnace door mechanisms

- Coiler mandrels

- Hot strip mill guides

Marine & Hydropower

- Ship rudder bearings

- Offshore platform cranes

- Dam gate hinges

- Hydraulic turbine bearings

- Lock gate mechanisms

- Underwater equipment

Mining & Construction

- Excavator boom pivots

- Crusher linkages

- Dragline bushings

- Shovel dippers

- Tunnel boring machines

- Conveyor take-up frames

Mold & Die Industry

- Injection molding tie bars

- Die casting platen guides

- Press slide gibs

- Blow molding clamps

- Automotive die wear plates

- Stamping press guides

Metallic vs. Polymer Bearings

| Property | Metallic (Graphite Bronze) | PTFE Composite | POM Composite |

|---|---|---|---|

| Max Temperature | 400°C | 280°C | 110°C |

| Static Load | > 100 N/mm² | 250 N/mm² | 250 N/mm² |

| Impact Resistance | Excellent | Good | Very Good |

| Water/Marine | Excellent (SL4) | Good | Limited |

| Contamination | Immune | Resistant | Tolerant |

| Dry Running | Maintenance-Free | Maintenance-Free | Requires Initial Grease |

| Best Application | Extreme environments | Dry, high-temp | Heavy loads, dirty |

Need Bearings for Extreme Environments?

Our engineering team specializes in metallic self-lubricating bearings for steel mills, mining, marine, and high-temperature applications. Get expert recommendations and custom solutions.

Contact an Engineer