PTFE

Polytetrafluoroethylene

The lowest friction polymer for self-lubricating bearings. PTFE enables maintenance-free operation in demanding applications from -200°C to +280°C.

What is PTFE?

PTFE (Polytetrafluoroethylene), commonly known by the DuPont brand name Teflon®, is a synthetic fluoropolymer renowned for its exceptionally low coefficient of friction — the lowest of any solid material. This unique property makes PTFE the ideal choice for self-lubricating bearings and bushings.

In bearing applications, PTFE is rarely used in pure form. Instead, it's combined with reinforcing fillers or bonded to metal substrates to create composite bearing materials that offer the friction benefits of PTFE with improved load capacity, wear resistance, and dimensional stability.

JBM utilizes PTFE in our Metal-Polymer Composite Bearings — a three-layer structure where PTFE-based material is bonded to a sintered bronze interlayer on a steel backing, creating bearings that handle high loads while maintaining the self-lubricating properties of PTFE.

Why PTFE for Bearings?

Lowest of any solid — enables oil-free operation

Extreme temperature stability

Inert to virtually all chemicals

Dimensionally stable in wet environments

PTFE Properties

| Chemical Name | Polytetrafluoroethylene |

| Abbreviation | PTFE |

| Trade Name | Teflon® (DuPont) |

| Density | 2.1 - 2.3 g/cm³ |

| Melting Point | 327°C (620°F) |

| Tensile Strength | 20-35 MPa |

| Hardness | Shore D 50-65 |

| Friction (Dry) | 0.04 - 0.10 |

| Max PV (Unfilled) | 0.10 N/mm²·m/s |

Pure PTFE Limitations

- Low load capacity

- High wear rate under load

- Cold flow (creep) under pressure

- Poor thermal conductivity

These limitations are overcome by using PTFE composites and metal-backed structures.

PTFE Fillers for Enhanced Bearing Performance

Pure PTFE has limited load capacity and wear resistance. By adding reinforcing fillers, we create PTFE composites optimized for specific bearing applications.

Glass Fiber

15-25% glass fiber dramatically improves wear resistance and load capacity. Reduces creep and increases dimensional stability. Best for general industrial applications.

Carbon / Graphite

Carbon fiber or graphite powder improves thermal conductivity, reducing heat buildup. Enhances wear resistance in dry running conditions. Ideal for high-speed applications.

Bronze Powder

Bronze filler significantly increases load capacity and thermal conductivity. The metallic particles help dissipate heat and resist deformation under heavy loads.

MoS₂ (Molybdenum Disulfide)

MoS₂ is a solid lubricant that further reduces friction, especially during start-up. Combined with PTFE, it provides exceptional dry-running performance in vacuum or inert atmospheres.

Aramid Fiber (Kevlar®)

Aramid fibers provide excellent wear resistance without damaging soft shafts. The non-abrasive nature makes this ideal for applications with stainless steel or aluminum shafts.

Proprietary Blends

JBM develops custom PTFE compound formulations combining multiple fillers to optimize performance for specific applications — balancing friction, wear, load, and temperature requirements.

How PTFE is Used in JBM Bearings

JBM incorporates PTFE into bearing designs in multiple ways, each optimized for different performance requirements.

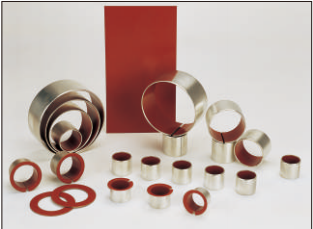

Metal-Polymer Composite

Three-Layer Structure

The PTFE/filler mixture is rolled into the porous bronze layer, creating a permanent mechanical bond. This design handles high loads (up to 250 N/mm²) while maintaining PTFE's low friction properties.

View Metal-Polymer Bearings →PTFE Lined Bronze

Wrapped Construction

Thin PTFE layer bonded to wrapped bronze strip. Combines the strength of bronze with PTFE's self-lubricating surface. Used in hydraulic and oscillating applications.

- High fatigue resistance

- Excellent for oscillating motion

- Thin wall design saves space

Fiber-Reinforced PTFE

Filament Wound

PTFE fabric wound with fiber reinforcement on steel or composite backing. High strength-to-weight ratio. Used in aerospace and high-performance applications.

- Lightweight design

- High strength

- Corrosion resistant

PTFE Thrust Washers

Axial Load Design

Flat PTFE composite washers for axial (thrust) loads. Steel-backed for structural support. Handles high compression loads in limited axial space.

- Compact axial design

- High thrust capacity

- Easy installation

PTFE vs. Other Bearing Materials

How does PTFE compare to other self-lubricating bearing materials? Each has distinct advantages depending on the application.

| Property | PTFE Composite | POM (Acetal) | Bronze | Nylon |

|---|---|---|---|---|

| Friction Coefficient | 0.04-0.15 | 0.15-0.35 | 0.10-0.20 | 0.20-0.40 |

| Max Temperature | +280°C | +110°C | +300°C | +100°C |

| Min Temperature | -200°C | -40°C | -40°C | -40°C |

| Chemical Resistance | Excellent | Good | Fair | Fair |

| Water Absorption | None | Low (0.2%) | None | High (2-3%) |

| Load Capacity* | 250 N/mm² | 80 N/mm² | 300+ N/mm² | 40 N/mm² |

| Dry Running | Excellent | Good (needs grease) | Poor (needs oil) | Fair |

| Speed Capability | High | Medium | Low-Medium | Medium |

| Best For | Maintenance-free, extreme conditions | Heavy load, low speed | Heavy load, lubricated | Light duty, low cost |

*Load capacity shown for metal-backed composite bearings

Where PTFE Bearings Excel

PTFE bearings are the preferred choice when maintenance-free operation, extreme temperatures, or chemical resistance are required.

Automotive

- Steering column bearings

- Shock absorber bushings

- Brake caliper guides

- Throttle body bushings

- Seat adjustment mechanisms

Hydraulics

- Cylinder rod guide bushings

- Piston wear rings

- Valve stems

- Pump bearings

- Actuator pivots

Food & Pharmaceutical

- Conveyor bearings (FDA compliant)

- Packaging machinery

- Mixing equipment

- Bottling lines

- Clean room equipment

Aerospace

- Control surface hinges

- Landing gear bushings

- Flap track bearings

- Actuator rod ends

- Antenna gimbals

Chemical Processing

- Valve bearings (corrosive media)

- Agitator supports

- Pump bushings

- Heat exchanger guides

- Filter press bearings

Office & Home

- Printer mechanisms

- Copy machine bearings

- Appliance hinges

- Furniture hardware

- Exercise equipment

PTFE-Based Bearings

JBM-50

Steel Bronze Powder with PTFE/Fibre

View Details →

JBM-40

Steel Bronze Powder with PTFE/Fibre

View Details →

JBM-11

Bronze Backed with Bronze Powder PTFE/Fibre

View Details →

JBM-50DH

Steel Bronze Powder with PTFE/Fibre

View Details →

JBM-50HP

Steel Bronze Powder with PTFE/Fibre

View Details →

JBM-50MP

Steel Bronze Powder with PTFE/Fluoropolymer

View Details →Need help selecting the right PTFE bearing for your application? Our engineers can recommend the optimal material and design.

Contact EngineeringReady to Specify PTFE Bearings?

JBM offers a complete range of PTFE composite bearings — from standard catalog parts to custom-engineered solutions. Get maintenance-free performance for your most demanding applications.

Request a Quote