Oil and Gas

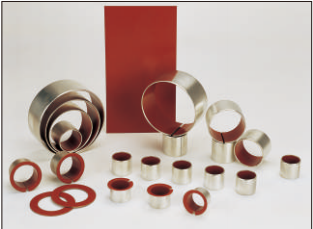

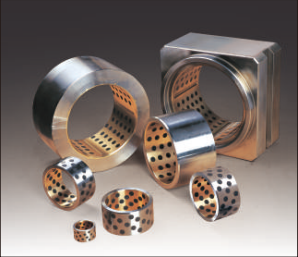

High-performance self-lubricating bearings engineered for the extreme demands of oil and gas exploration and production.

Engineered for the Energy Sector's Toughest Challenges

Design engineers in the oil and gas industry face numerous challenges when selecting bearing components. Bearings must withstand extreme operating conditions, including high pressure, temperature, and vibration, while resisting corrosion from harsh elements like seawater and chemicals. They must endure heavy loads and high stress, often in remote or offshore locations, requiring long-term durability and reliability. Bearings also need to handle abrasion and contamination while supporting proper lubrication in difficult conditions.

JBM's bearing solutions are specifically designed to meet the demanding conditions of the oil and gas industry. Our bearings offer high load and stress resistance, along with exceptional durability in extreme temperatures, pressures, and corrosive environments. With self-lubricating properties and low-maintenance designs, JBM bearings excel in reducing friction and enhancing energy efficiency while minimizing downtime. Our solutions ensure reliable performance and compliance with industry standards.

Consult an EngineerOil & Gas Applications

The JBM Advantage

Extreme Operating Conditions

JBM bearings are designed to perform reliably under extreme pressures, temperatures, and vibrations in remote, hazardous environments typical in oil and gas operations.

Corrosion Resistance

We offer corrosion-resistant bearings that withstand exposure to seawater, chemicals, and hydrocarbons, ensuring long-term reliability in offshore and onshore applications.

Heavy Loads & High Stress

Our bearings are built to handle heavy loads and high mechanical stress typical in oil and gas equipment like pumps, compressors, and drilling machinery.

Abrasion & Contamination Resistance

JBM bearings are made from materials that resist abrasion and contamination, extending component lifespan in harsh, particle-laden environments.

Self-Lubricating Design

JBM's self-lubricating and low-maintenance bearings reduce the challenges of maintaining proper lubrication in extreme and remote conditions.

Noise & Vibration Control

Our bearings help minimize noise and vibrations, improving equipment performance and safety in demanding working environments.

Long-Term Durability

Our solutions are engineered for durability, minimizing the need for frequent maintenance and ensuring reliable performance in remote locations.

Power Your Energy Operations with JBM

From offshore platforms to drilling rigs, our self-lubricating bearings deliver the reliability and durability your oil and gas applications demand. Let's discuss your project requirements.

Contact Us