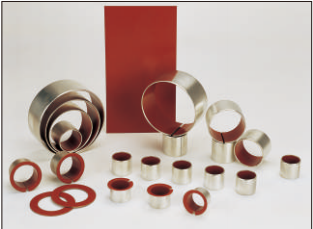

Metal-Polymer Composite Bearings

Self-lubricating bearings combining steel backing, sintered bronze, and PTFE-based polymer for exceptional dry-running performance and minimal maintenance.

Multi-Layer Composite Technology

Metal-polymer composite bearings are engineered with a unique tri-layer structure that delivers exceptional performance in demanding applications. The composite design combines the mechanical strength of metal with the low-friction properties of advanced polymers.

Steel Backing

Low-carbon steel provides high load-carrying capacity, excellent heat dissipation, and structural rigidity for press-fit installation.

Porous Bronze Layer

Sintered bronze powder (0.20-0.35mm) maximizes thermal conductivity and serves as a reservoir for the polymer overlay.

PTFE-Based Polymer Overlay

Anti-friction layer enriched with PTFE, fibers, or solid lubricants provides self-lubrication and forms a protective transfer film on mating surfaces.

Key Specifications

Why Choose Metal-Polymer Composite Bearings

Dry Running Capability

Self-lubricating design enables operation without external lubrication, ideal for applications where oil or grease is impractical.

Low Friction

PTFE-based overlay delivers friction coefficients as low as 0.03, reducing energy consumption and wear on mating surfaces.

Maintenance-Free

Eliminates the need for regular lubrication, reducing maintenance costs and equipment downtime significantly.

Wide Temperature Range

Operates reliably from cryogenic conditions (-195°C) to high temperatures (+280°C), suitable for extreme environments.

Chemical Resistance

Excellent resistance to chemicals, fuels, and hydraulic fluids. Low water absorption prevents swelling and dimensional changes.

Rotary & Oscillating Motion

Suitable for rotating, oscillating, and reciprocating movements. Transfer film protects mating surfaces during operation.

Compact Design

Thin-wall construction allows for very small radial design envelopes, ideal for space-constrained applications.

Low Noise Operation

Runs quietly without the stick-slip noise common in traditional bearings, perfect for automotive and office equipment.

We typically respond to inquiries within 12 hours. Get expert recommendations for your application.

Get a QuoteWhere They're Used

Automotive

- Steering systems & gear pumps

- Shock absorbers & struts

- Transmission components

- Door, hood & trunk hinges

- Brake calipers & pistons

- Windshield wiper motors

Hydraulics

- Gear & vane pumps

- Axial & radial piston pumps

- Hydraulic cylinders

- Valve actuators

- Fluid power systems

- Compressors

Industrial

- Textile machinery

- Packaging equipment

- Food processing machines

- Office automation (OA)

- Medical devices

- Material handling

Home & Consumer

- Refrigerators & HVAC

- Washing machines

- Sewing machines

- Power tools

- Fitness equipment

- Consumer electronics

Metal-Polymer Composite Bearings Range

JBM-50

Steel Bronze Powder with PTFE/Fibre

View Details →

JBM-40

Steel Bronze Powder with PTFE/Fibre

View Details →

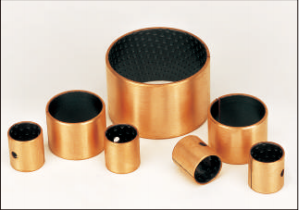

JBM-11

Bronze Backed with Bronze Powder PTFE/Fibre

View Details →

JBM-50DH

Steel Bronze Powder with PTFE/Fibre

View Details →

JBM-50HP

Steel Bronze Powder with PTFE/Fibre

View Details →

JBM-50MP

Steel Bronze Powder with PTFE/Fluoropolymer

View Details →

JBM-12

Steel with PTFE Tape

View Details →

JBM-25

Aluminum Alloy with PTFE Tape

View Details →

JBM-FR

Bronze Mesh + PTFE/Solid Lubricants

View Details →

JBM-20

Steel Bronze Powder with POM

View Details →

JBM-22

Steel Bronze Powder with PVDF/PTFE

View Details →

JBM-80

Steel Bronze Powder with PEEK/PTFE

View Details →Need Help Selecting the Right Bearing?

Our engineering team can help you choose the optimal metal-polymer composite bearing for your application. Get expert recommendations, technical datasheets, and samples.

Contact an Engineer