Primary Metals

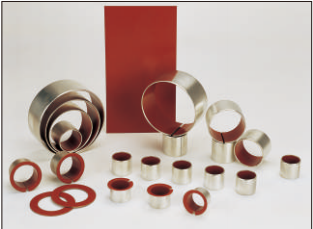

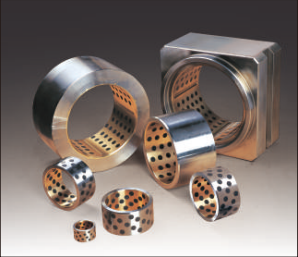

Maintenance-free self-lubricating bearings engineered for the extreme demands of steel plants and foundries.

Engineered for Steel Plants and Foundries

In the primary metals industry, equipment endures extreme, abrasive conditions where regular maintenance is challenging. Design engineers must create solutions that ensure efficient, long-lasting performance in these harsh environments, minimizing the need for upkeep while maintaining operational reliability under intense heat and heavy loads.

JBM's self-lubricating, maintenance-free bearings are designed to thrive in demanding steel plants and foundries. Our advanced bearing solutions enhance durability and extend equipment life, with designs tailored to meet the specific needs of each application. From continuous casting to rolling mills, JBM bearings deliver consistent performance where others fail.

Consult an EngineerPrimary Metals Applications

The JBM Advantage

Extreme Operating Conditions

JBM bearings are engineered to perform reliably in high-temperature, abrasive environments, ensuring longevity and consistent performance despite harsh conditions.

Heavy Loads & High Stress

Our bearings are built to withstand the intense pressures of heavy-duty applications, delivering superior load capacity and stress resistance in demanding metal processing.

Maintenance-Free Operation

JBM's self-lubricating bearings minimize the need for external lubrication, providing reliable operation without regreasing and routine maintenance requirements.

Corrosion Resistance

Our bearings are crafted from materials that resist corrosion, safeguarding performance in the presence of moisture, chemicals, and other corrosive substances.

Noise & Vibration Control

JBM bearings are designed to mitigate noise and vibration, contributing to quieter, smoother operation and reducing wear on equipment.

Durability & Longevity

Our maintenance-free bearings provide extended service life, reducing downtime and maintenance needs, ensuring continuous, efficient operation in demanding environments.

Energy Efficiency

By reducing friction, JBM bearings enhance energy efficiency, lowering power consumption and optimizing the overall performance of industrial equipment.

Optimize Your Metal Processing Operations

From steel mills to foundries, our maintenance-free bearings deliver the durability and reliability your primary metals applications demand. Let's discuss your project requirements.

Contact Us