JBM-20

Steel Bronze Powder with POM

Features & Benefits

The JBM-20 is engineered for marginally lubricated applications involving rotating or oscillating movements. Its acetal copolymer (POM) lining allows for extended re-lubrication intervals, significantly reducing maintenance requirements. The material exhibits excellent damping properties and is highly resistant to shock loads and edge loading misalignment. Furthermore, it absorbs practically no water, ensuring dimensional stability and no swelling even in humid environments. It is recommended to pre-lubricate the bearing upon assembly.

Structure

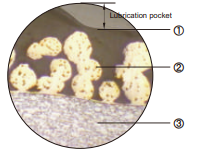

| Layer | Material | Thickness | Function |

|---|---|---|---|

| 1 | POM (Polyoxymethylene) | 0.30~0.50mm | Provides high wear resistance and low friction. The surface features a pattern of circular indents (lubrication pockets) designed to retain grease, ensuring performance even with minimal lubricant supply. |

| 2 | Sintered bronze powder | 0.20-0.35mm | Ensures maximum thermal conductivity away from the bearing surface and serves as a mechanical anchor for the POM resin layer. |

| 3 | Low-carbon steel | Base | Delivers exceptionally high load-carrying capacity and excellent heat dissipation. |

Technical Data

max load

- static 250 N/mm²

- very low speed 140 N/mm²

- rotating oscillating 70 N/mm²

max pv

temperature limit

friction coefficient

max speed

- pre lubricated 2 m/s

- continuous oiling grease >2 m/s

thermal conductivity

coefficient of thermal expansion

Typical Applications

Automotive

Extensively used in heavy-duty chassis components such as suspension joints, kingpin assemblies, stub axles, steering linkages, and rear chassis hinges.

Learn More

Agricultural Machinery

Ideal for robust machinery including harvester pivots, bale trips, wheel caster swivels, and front axle pivot bearings.

Learn More

Mining & Quarrying

Machine tool applications such as spindles in drilling, grinding, and milling machines, as well as ram guide plates in multi-ram presses.

Learn MoreLooking for other bearing solutions?

Browse All ProductsNeed Help with JBM-20?

Our engineering team can help you determine if this bearing is right for your application. Get personalized recommendations, technical datasheets, and competitive pricing.

Contact Us