JBM-25

Aluminum Alloy with PTFE Tape

Features & Benefits

The JBM-25 distinguishes itself with an aluminum alloy backing, offering a significant weight reduction that facilitates easier handling and installation. Engineered for dry-running environments, it exhibits a low coefficient of friction, minimal wear, and superior sliding characteristics. The bearing generates a transfer film that protects mating metal surfaces and is highly versatile, supporting rotary, linear, and oscillating movements.

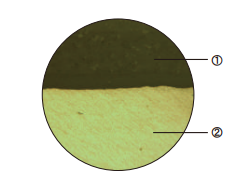

Structure

| Layer | Material | Thickness | Function |

|---|---|---|---|

| 1 | PTFE tape | - | A very thick PTFE layer that effectively isolates noise and allows for the design of clearance-free applications. |

| 2 | Aluminum alloy backing | Base | Provides exceptionally high load-carrying capacity, excellent heat dissipation, and a lightweight structural solution. |

Technical Data

max load

- static 80 N/mm²

- very low speed 40 N/mm²

- rotating oscillating 20 N/mm²

max pv dry running

- short term operation 2.8 N/mm²*m/s

- continuous operation 1.8 N/mm²*m/s

temperature limit

friction coefficient

max speed

- dry running 1 m/s

- hydrodynamic operation >1 m/s

thermal conductivity

coefficient of thermal expansion

Typical Applications

Recreation & Sports

Leveraging its lightweight aluminum construction, the JBM-25 is the ideal solution for applications where weight reduction is critical. It is widely employed in office automation (OA) systems, fitness equipment, bicycles, and motorcycles.

Learn More

General Industrial

Due to its clean and corrosion-resistant nature, it is also frequently used in food processing and packaging machinery.

Learn MoreLooking for other bearing solutions?

Browse All ProductsNeed Help with JBM-25?

Our engineering team can help you determine if this bearing is right for your application. Get personalized recommendations, technical datasheets, and competitive pricing.

Contact Us