Metal-Polymer Composite Bearings

JBM-50DH

Steel Bronze Powder with PTFE/Fibre

PRODUCT OVERVIEW

Features & Benefits

Built upon the foundation of the standard JBM-50 series, the JBM-50DH is distinguished by an enhanced sliding layer thickness. This design facilitates post-assembly machining, enabling precise calibration of clearance or interference fits. Consequently, it ensures sustained operational stability under specific torque conditions and effectively maintains torque attenuation within optimal limits.

MATERIAL COMPOSITION

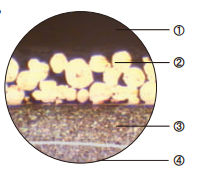

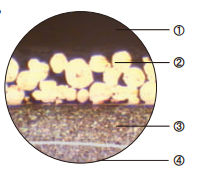

Structure

| Layer | Material | Thickness | Function |

|---|---|---|---|

| 1 | PTFE/Fibre mixture | 0.03-0.08mm | Provides an excellent initial transfer film, effectively coating the mating surfaces of the bearing assembly to form an oxide-type solid lubricant film. |

| 2 | Sintered bronze powder | 0.20-0.35mm | Ensures maximum thermal conductivity away from the bearing surface and serves as a reservoir for the PTFE mixture. |

| 3 | Low-carbon steel | Base | Delivers exceptionally high load-carrying capacity and excellent heat dissipation. |

| 4 | Plating | - | Provides good corrosion resistance. |

SPECIFICATIONS

Technical Data

max load

- static 250 N/mm²

- very low speed 140 N/mm²

- rotating oscillating 60 N/mm²

max pv dry running

- short term operation 3.6 N/mm²*m/s

- continuous operation 1.8 N/mm²*m/s

temperature limit

-195℃ ~ +280℃

friction coefficient

0.05~0.20

max speed

- dry running 2 m/s

- hydrodynamic operation >2 m/s

thermal conductivity

42 W(m*K)⁻¹

coefficient of thermal expansion

11*10⁻⁶*K⁻¹

WHERE IT'S USED

Typical Applications

Looking for other bearing solutions?

Browse All ProductsNeed Help with JBM-50DH?

Our engineering team can help you determine if this bearing is right for your application. Get personalized recommendations, technical datasheets, and competitive pricing.

Contact Us