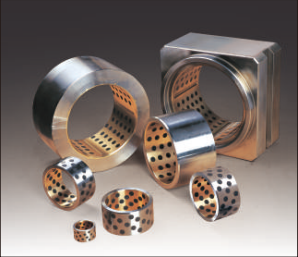

JBM-650GT

Steel Shell Cast Bronze Bearings with Graphite Plugs

Features & Benefits

The JBM-650GT combines the high mechanical strength of a steel backing with the self-lubricating properties of a graphite-plugged bronze liner. This design offers an economical solution for low-speed and high-load applications where external lubrication is impractical. It provides excellent resistance to shock loads, reduces the coefficient of friction, and ensures reliable self-lubricating performance.

Structure

| Layer | Material | Thickness | Function |

|---|---|---|---|

| Bi-metallic: Steel Shell + Cast Bronze Liner with Graphite | Sintered/Cast Layer on Steel | This bearing features a unique bi-metallic structure consisting of a steel shell backing lined with a cast bronze bearing material. Specially formulated solid lubricants (graphite) are embedded into holes within the bronze liner. The bronze is cast onto the steel using a process that achieves an integral metallurgical structure, significantly increasing load-carrying capacity while reducing material costs compared to solid bronze bearings. |

Technical Data

max load

- static 250 N/mm²

- dynamic 100 N/mm²

max speed

- dry 0.5 m/s

- lubricated 1.0 m/s

max pv

bronze alloy hardness

interlay bonding strength

temperature limit

friction coefficient

thermal conductivity

coefficient of thermal expansion

Typical Applications

Construction & Heavy Equipment

The JBM-650GT is widely used in high-temperature and high-load environments with low speeds, such as continuous casting machinery in steel plants and mineral/mining machinery.

Learn More

Oil & Gas

It is also applicable in injection molding machinery and dockside machinery, offering a robust and cost-effective alternative to solid bronze bearings.

Learn MoreLooking for other bearing solutions?

Browse All ProductsNeed Help with JBM-650GT?

Our engineering team can help you determine if this bearing is right for your application. Get personalized recommendations, technical datasheets, and competitive pricing.

Contact Us